Bringing a product to market comes with challenges, from compliance and production scaling to design refinements and component obsolescence. Our expert support helps you navigate every stage, keeping your project on track and built for success.

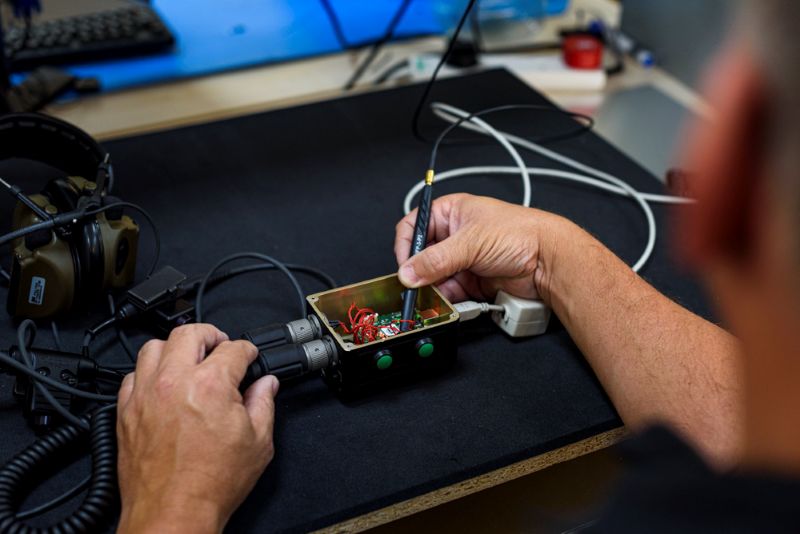

Every electronic product must meet specific regulatory standards before it can be certified for market entry. These standards vary depending on the product type and technology used but typically include electromagnetic compatibility (EMC) testing, safety testing, and other assessments applicable to your product and technology. Successfully passing these tests is essential for securing CE, UKCA, FCC, or other global certifications.

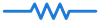

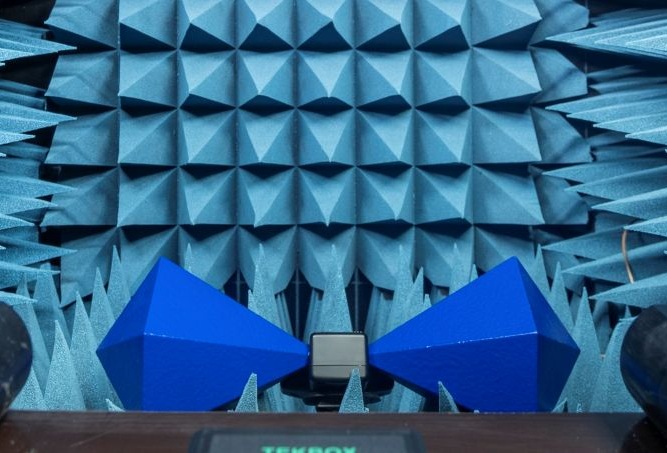

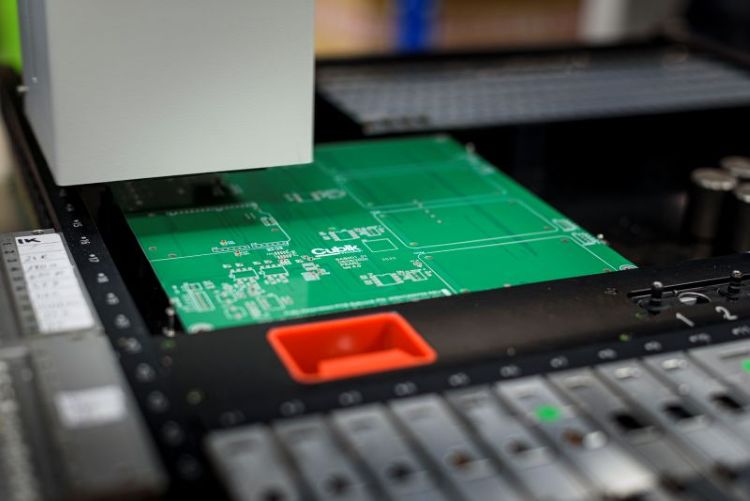

At Cubik EPS, we conduct pre-compliance tests that replicate the formal certification conditions your product will face. This allows us to identify potential issues early and mitigate compliance risks before the official testing stage, reducing the likelihood of costly failures, redesigns, and delays.

Cubik EPS can carry out the following EMC tests and debug:

Our expertise in EMC and safety testing ensures that your product is fully prepared for the certification process, giving you confidence in a smooth and successful approval.

Bringing a product to market requires more than just innovation - it requires a deep understanding of compliance requirements. We provide expert support throughout the entire compliance journey. From EMC testing and safety testing to radio testing for wireless technologies like Bluetooth, Wi-Fi, and cellular, we ensure your product is tested against the relevant regulatory standards.

We work with UK-based accredited test laboratories, guiding you through the complex process to ensure your product is tested to the highest standards. Beyond testing, our full compliance service includes the generation of a technical file to ensure all necessary documentation is in place to support your product marks.

As electronic components become obsolete, the risk of production delays and rising costs increases, threatening your product’s long-term viability. Cubik EPS provides expert obsolescence support services to help you navigate these challenges and keep your products on track.

We offer tailored solutions for sourcing alternative components, redesigning products for newer or alternative parts, and securing long-term supply chains to ensure your product remains available and cost-effective. We work closely with you to minimise disruptions and maintain smooth production, so you can continue to meet demand and extend the lifespan of your product.

Ensure your electronic product is built on a solid foundation with our comprehensive technical design reviews. Our experts meticulously analyse your schematics and PCB layouts, identifying potential design flaws before they become costly problems.

Whether you're developing a new product or refining an existing design, our technical design reviews help you avoid common pitfalls and ensure your design meets industry standards. By partnering with Cubik EPS, you can trust that your product is designed to perform, with manufacturability in mind, and meets both your technical and commercial expectations

You've got prototypes - your product works and performs as expected, but scaling up production presents new challenges. Whether the cost is too high, the manufacturing process is complex, or you’re looking for low-mid volume production, we can help.

Our expertise in design for manufacture (DFM) ensures that your product is optimised for cost-effective production without compromising on quality. We help streamline the manufacturing process, identify efficiencies, and find solutions that make scaling up smoother and more affordable.

Accurate and repeatable testing is essential for ensuring your electronic product meets both performance and regulatory standards. We design custom test fixtures that streamline the testing process, improving accuracy and efficiency.

Our expert team works with you to develop test fixtures tailored to your product, ensuring every component is thoroughly validated during the design, prototyping, and production phases. By optimising your testing process, we help you meet the highest quality control standards, reduce errors, and maintain product consistency.